Henkel will launch a new generation of cartridges across its broad portfolio of construction adhesives and sealants marketed under well-known brands such as Pattex, Sista, Rubson, Unibond, and Moment. The innovative design has been developed to significantly improve the sustainability of the products while uniquely enhancing the convenience for users. As part of a comprehensive program, the roll-out will start in September 2025 across Europe in the category of sanitary and multi-purpose silicone sealants.

Cartridge technology has been developed since the 1930s without any major innovations over the last 80 years. Current solutions not only require tools and time for preparation but also generate substantial plastic waste. As part of its ambitious sustainability targets, Henkel initiated various projects globally to significantly innovate the cartridge technology without compromising the product performance and the habits of users.

“Our new cardboard-based cartridge technology required two years of engineering, development, and testing with more than 3,000 professional and DIY users,” explained Baptiste Chieze, Director Marketing, Digital & E-Commerce for consumer adhesives at Henkel. “As a result, we can now present a next-generation solution that combines significant sustainability improvements with more convenient functionality – without compromising on the product performance that our brands are known for. We are convinced that the cartridges will become a key differentiator in the sealants and construction adhesives market as they perfectly respond to the needs and expectations of the users.”

Conventional cartridges are mainly made of plastic. After usage the entire pack must be disposed of in non-circular waste streams as the materials are contaminated with adhesive or sealant residues. The new Henkel cartridge solution consists of five different key components: The top cap and the nozzle, the ring and the piston– all made from at least 49 percent recycled plastic – the exterior tube based on 100 percent recycled cardboard and the inner foil sausage. Thus, the amount of plastic per unit is reduced by at least 51 percent compared to current standard cartridges. Additionally, the non-recyclable contaminated parts (top cap, nozzle, piston, and inner foil sausage) can be fully separated and disposed of in general waste, while the rest of the cartridge (carboard and ring) can be disposed of in the regular recyclable household waste system. This helps to reduce the amount of non-recyclable waste per cartridge by 73%.

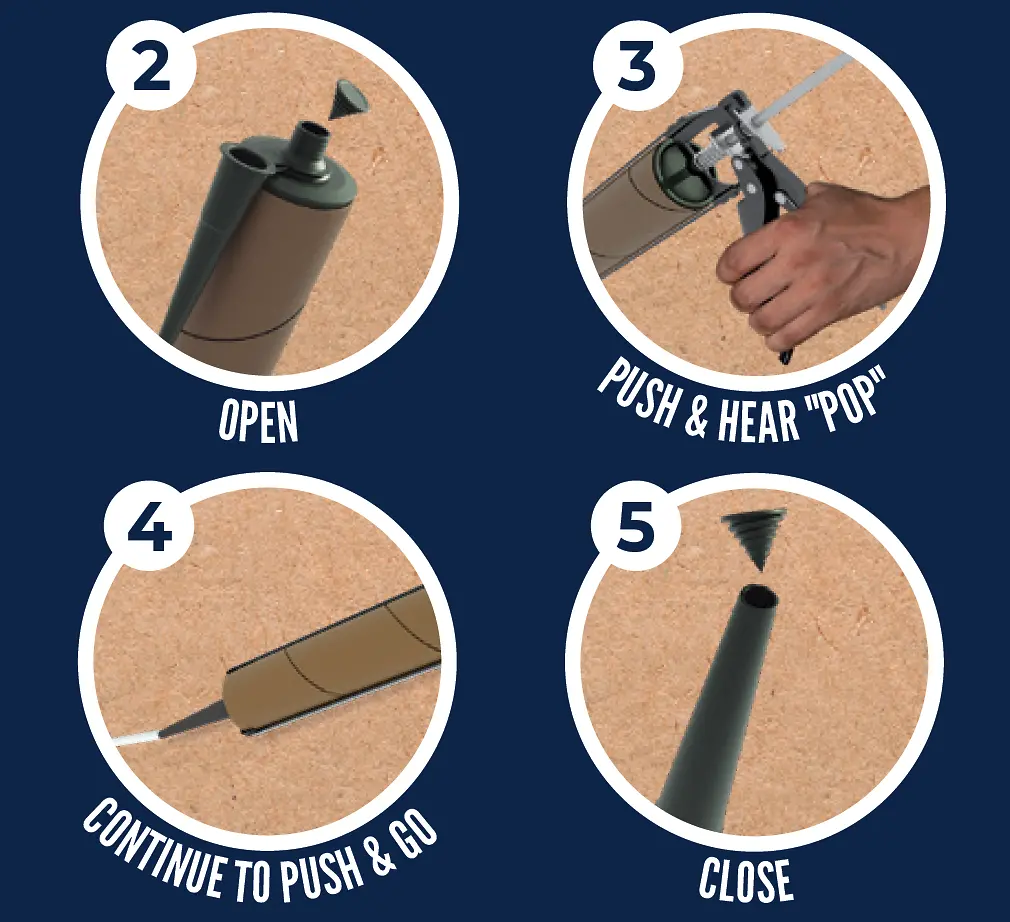

Henkel´s novel cartridge technology not only provides significant sustainability improvements but has also been developed to enhance the user experience. The new top cap enables auto-opening in just one step without the need for any tools such as cutters or scissors. Users only need to attach the nozzle. Thus, the auto-opening not only improves the safety for users but also simplifies and accelerates the application. Moreover, the new cartridges can be used in the same way as current plastic cartridges with existing cartridge guns. Users will benefit from the traditional Henkel quality in a convenient and sustainable format with no changes in product performance or formulation. Additionally, if the product is not completely used up, the cartridge can be easily closed with the cap to allow the reusage later on.

Henkel will roll out its new cartridge technology for its sealants and construction adhesives portfolio in Europe over the coming years. The market launch will start in September 2025 with the conversion in the category of sanitary and multi-purpose silicone sealants, followed by a comprehensive second wave following in 2026. As part of its sustainability program the company will also explore the market potentials for cardboard cartridges in other regions with intensive user testing over the coming years.