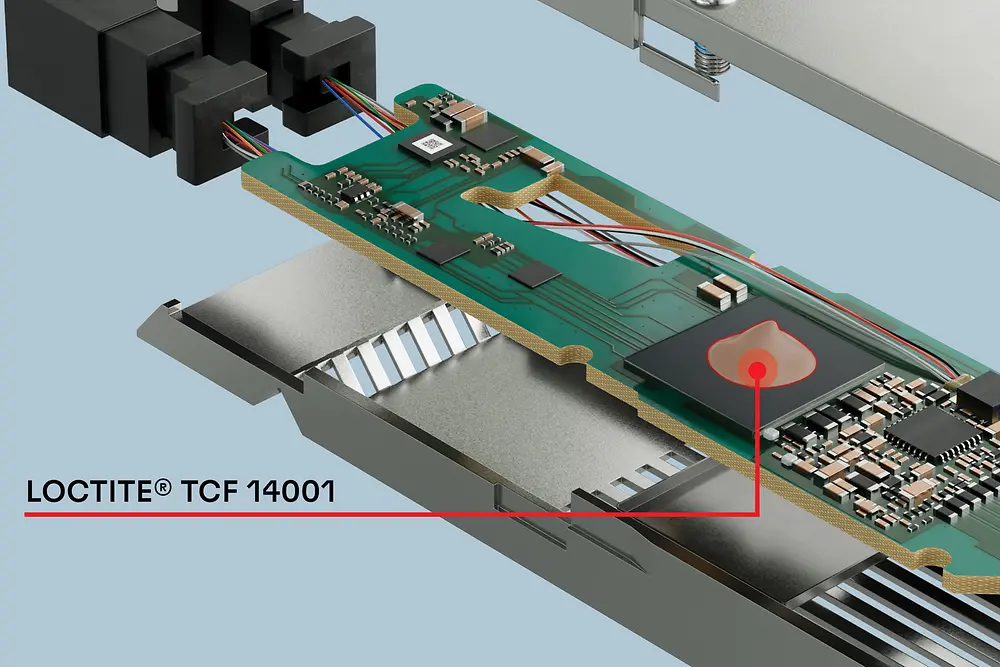

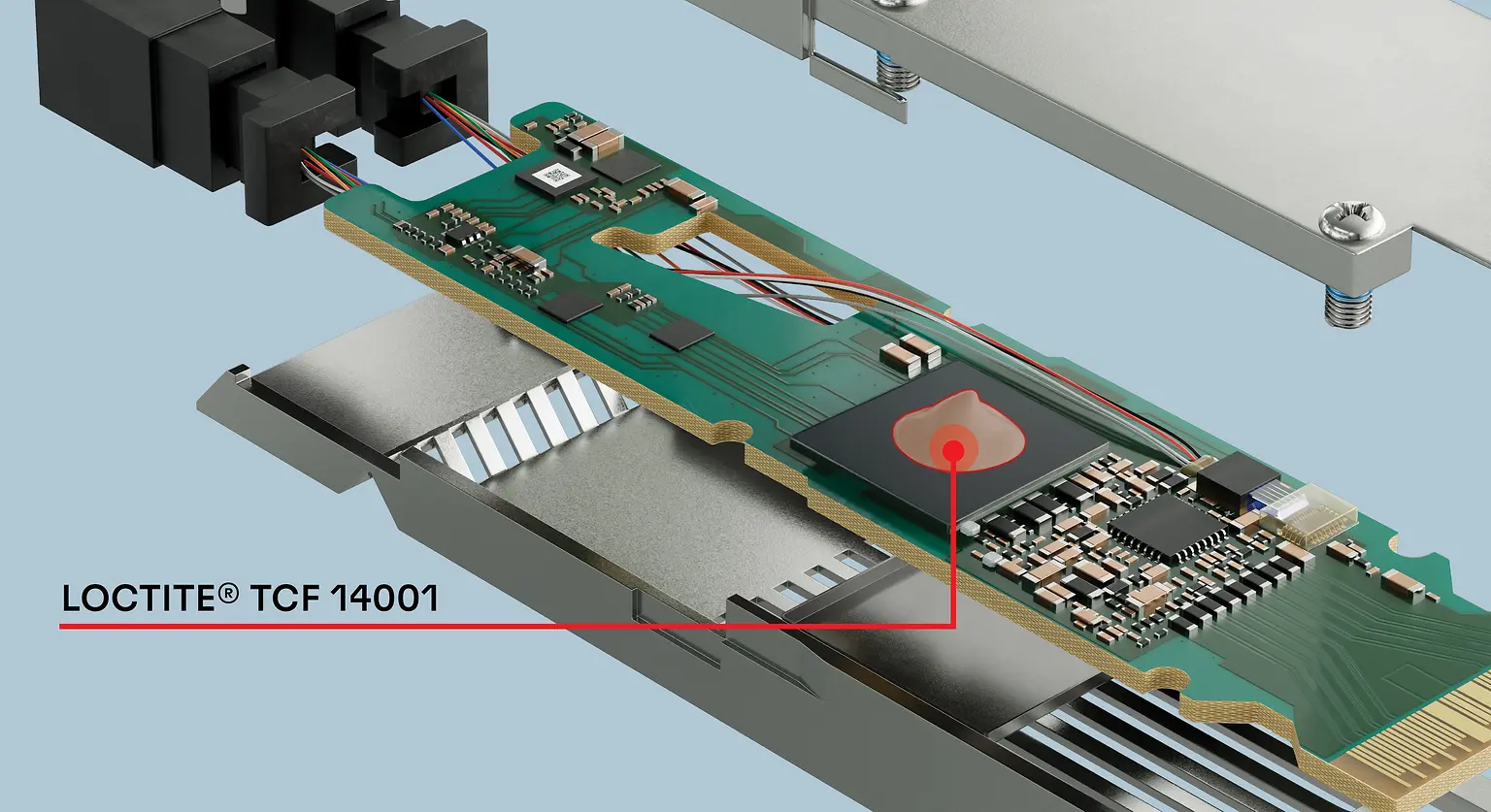

Escalating AI workloads pose significant bandwidth and latency challenges that can only be addressed by more powerful, high-speed optical technology. While next-generation 800G, 1.6T, and coherent optical transceivers are meeting speed, distance, latency, and bandwidth demands, their high-power density chip designs result in increased heat generation. Exceptional thermal control is required to fully exploit their performance potential.

Commenting on Henkel’s efforts to address the functional heat challenges of newer optical technologies, Henkel Data and Telecom Global Market Strategy Manager Tracy Lin says: “The thermal conductivity level of our latest gap filler formulation is a first for liquid TIMs. This capability is of primary importance for high-speed transceivers, but the material must also align with mass production, deployment in sensitive optical environments, and operational durability. Processability and in-application reliability are vital, and Loctite TCF 14001 meets these expectations.”

A low-volatility, two-part silicone material, Loctite TCF 14001 exhibits minimal outgassing (<100 ppm silicone volatiles) and very low oil bleed, protecting against any optical interference. The unique filler technology of the TIM formulation enables highly precise automated dispensing with stable flow, while its strong interface adhesion and good gap variation tolerance across a range of chip sizes ensure thermal performance continuity even when high thermal loads may induce stress and chip warpage.

In addition to its success with AI data center optical devices, Loctite TCF 14001’s application scope extends to numerous other markets where automated, low thermal impedance, high thermal conductivity TIM solutions are necessary. These include telecom, automotive, power generation, and industrial automation, among others.

Visit this resource for more information about Loctite TCF 14001.